Clean Booth is a mobile, flexible cleanroom solution that meets the requirements of contamination control in pharmaceuticals, food, cosmetics and electronics. Choosing a GMP-certified Clean Booth supplier helps businesses ensure product quality, optimize costs and meet international standards.

- 1. Clean Booth and Its Role in GMP Production

- 2. GMP Standards for Clean Booths

- 3. Reasons to Choose a Clean Booth Supplier in Vietnam Instead of Importing Turnkey Units

- 4. Trusted Clean Booth Supplier in Vietnam

- 5. GMP-Compliant Clean Booth Implementation Process

- 6. Practical Applications of Clean Booths in Vietnam

- 7. Frequently Asked Questions About GMP-Compliant Clean Booths

- 8. Contact VCR to receive offers and support from experts

1. Clean Booth and Its Role in GMP Production

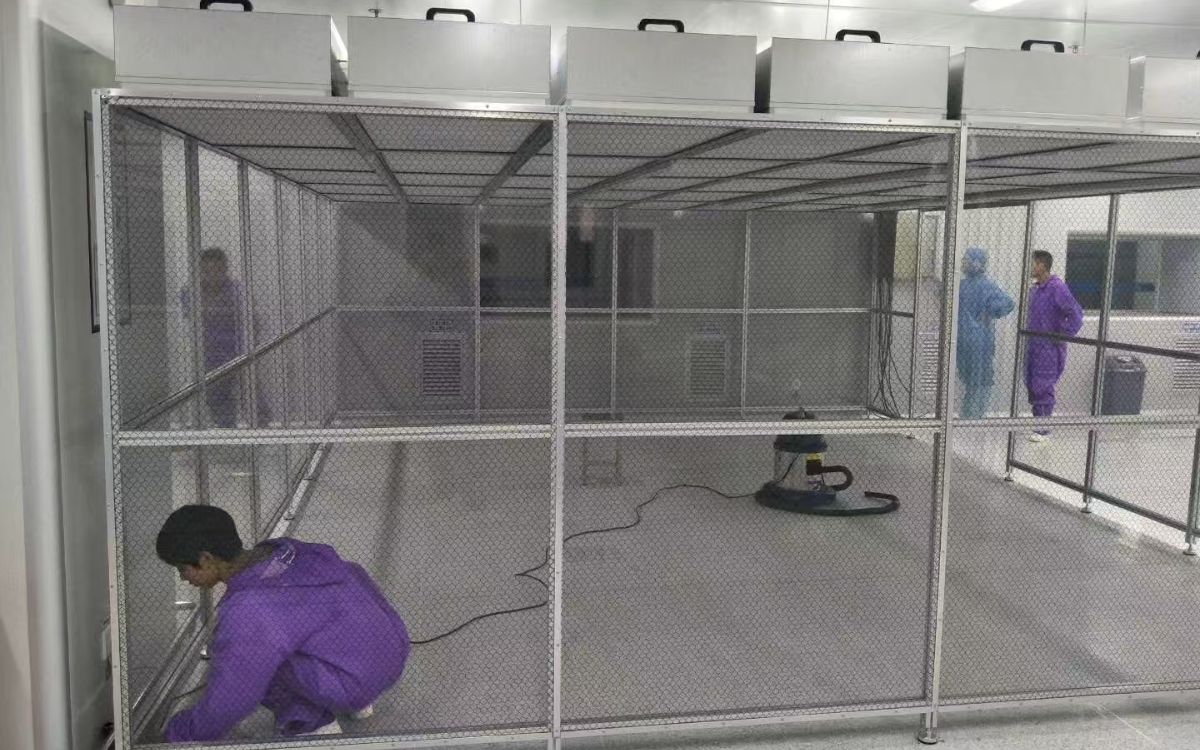

A Clean Booth can be simply understood as a mobile clean space, designed in a modular form that can be quickly assembled at any position within a factory. Instead of constructing an entire fixed cleanroom with high costs and long construction time, a Clean Booth offers a flexible solution, allowing the creation of a local contamination-controlled area within a small footprint, suitable for each production stage. This is precisely the difference that makes the Clean Booth one of the most popular devices in industries that demand sterile and safe environments.

In the pharmaceutical industry, Clean Booths are often positioned in weighing areas where fine dust and microorganisms need to be prevented from spreading. In the food sector, Clean Booths play an important role in packaging zones, ensuring that products are not cross-contaminated before reaching the market. In the cosmetics industry, Clean Booths are used to protect filling, tube sealing, and bottling processes, maintaining purity and high-quality standards for the finished products. In electronics, especially in semiconductor, sensor, and precision component manufacturing, Clean Booths provide a stable clean airflow environment, preventing dust and particles from affecting microscopic accuracy.

The reason why GMP (Good Manufacturing Practice) requires factories to use devices such as Clean Booths lies in the principle of strict quality control right from the production environment. GMP emphasizes the rule of “prevention rather than correction”: if a clean environment is not maintained, the risks of contamination, cross-contamination, or dust will directly impact product safety and effectiveness. A Clean Booth meets this requirement by generating laminar airflow through HEPA or ULPA filters, thereby eliminating dust particles, microorganisms, and ensuring that the production area consistently meets cleanroom standards. Therefore, the presence of a Clean Booth is not just a convenient option but has become a mandatory requirement for enterprises seeking GMP certification and maintaining brand reputation in the market.

2. GMP Standards for Clean Booths

For a Clean Booth to be recognized as GMP-compliant, it must not only provide convenience and the ability to create clean zones but also strictly adhere to standardized technical criteria. First of all, the construction materials must ensure durability and safety. Typically, the frame and surfaces of Clean Booths are made of stainless steel SUS304 - a type of steel resistant to corrosion and chemicals, particularly suitable for pharmaceutical, food, and cosmetics production environments. The surrounding panel boards must provide insulation, anti-static capability, and a smooth, seamless surface to prevent dust and microorganisms from accumulating. This forms the foundation for a Clean Booth to sustain a stable and long-lasting clean environment.

Another crucial factor is the air filtration system. GMP requires Clean Booths to be equipped with HEPA or ULPA filters with an efficiency of at least 99.97% at 0.3 microns. As a result, fine dust, bacteria, and airborne contaminants are effectively removed before clean air is delivered into the workspace. This is a mandatory condition to ensure that the environment inside a Clean Booth complies with ISO 14644 cleanroom classifications, the international standard for evaluating cleanliness in controlled environments.

Beyond filtration, airflow control must be scientifically designed. GMP clearly states that air within clean zones must be stable, without turbulence or dead zones. Therefore, Clean Booths are often designed with laminar airflow, either vertically from top to bottom or horizontally, with consistent velocity. Additionally, fans and filters are arranged to maintain positive pressure, preventing unfiltered air from entering. This principle allows Clean Booths to sustain optimal isolation and absolute protection for products and materials throughout operations.

Another important GMP standard is flexibility and long-term operability. Clean Booths must be modular in design, allowing them to be expanded or reduced depending on production scale. This enables enterprises to relocate or reinstall Clean Booths without altering the entire cleanroom system. Furthermore, components such as fans, HEPA filters, lighting, or panels must be easy to assemble and maintain, ensuring that replacements, cleaning, and periodic validations can be carried out seamlessly. Only when these conditions are fully met can a Clean Booth truly be recognized as GMP-compliant and deliver long-term value to enterprises.

3. Reasons to Choose a Clean Booth Supplier in Vietnam Instead of Importing Turnkey Units

When implementing cleanroom systems, many enterprises often face the choice: should they import turnkey Clean Booths from overseas or work with a reliable domestic supplier? In practice, collaborating with Clean Booth manufacturers and distributors in Vietnam provides significant advantages, particularly regarding GMP requirements and industry-specific needs.

The first reason lies in the thorough understanding of GMP standards within Vietnam. Although GMP is an international framework, when applied domestically, local authorities often issue specific guidelines and regulations adapted to Vietnam’s production environment and regulatory conditions. Local suppliers are well-versed in these requirements and can therefore design and recommend Clean Booths that align with the Ministry of Health’s criteria, helping enterprises avoid “off-standard” issues or repeated adjustments during inspections.

The second factor is cost and lead-time optimization. Importing turnkey Clean Booths usually involves expenses such as shipping, import duties, and delays caused by customs clearance or logistics fluctuations. By working with domestic suppliers, businesses can significantly reduce costs while shortening installation schedules, enabling faster commissioning of production lines. This becomes a critical advantage, especially for GMP projects that are often under tight delivery deadlines.

Equally important is the availability of local warranty and maintenance services. Like all cleanroom equipment, Clean Booths require regular inspections, filter replacements, and timely troubleshooting. If a system is imported as a turnkey solution, enterprises may have to wait for foreign experts or face difficulties sourcing spare parts. In contrast, domestic suppliers in Vietnam provide immediate technical support, ensuring stable operations and minimizing risks of production downtime.

Finally, local suppliers offer highly flexible customization for each project. Every industry and facility has unique requirements: varying cleanroom scales, diverse production lines, or challenging environments such as high humidity, extreme temperatures, or higher-than-standard cleanliness levels. A Vietnamese supplier can tailor Clean Booths according to customer needs, from dimensions and materials to filtration systems and airflow design, guaranteeing absolute compatibility with real-world production demands.

For these reasons, instead of relying on imported turnkey solutions, partnering with a Clean Booth supplier in Vietnam not only helps enterprises save costs and optimize schedules but also ensures sustainability and adaptability throughout operations. It is a strategic solution that balances international compliance with local practicality.

4. Trusted Clean Booth Supplier in Vietnam

To select a Clean Booth that meets GMP standards, not only must the equipment itself comply with technical requirements, but the supplier also plays a decisive role in ensuring quality, schedule, and after-sales service. In Vietnam, one of the most trusted suppliers among pharmaceutical, food, cosmetics, and electronics enterprises is Vietnam Cleanroom (VCR).

VCR is recognized as a pioneering brand in the cleanroom industry, with over a decade of experience implementing projects compliant with GMP-WHO, ISO 14644, and other international standards. VCR’s strength lies in supplying Clean Booths manufactured on modern production lines, using premium materials such as SUS304 stainless steel, anti-dust surface panels, and HEPA/ULPA filters imported directly from globally reputable brands. All products are quality-tested before delivery and come with complete technical documentation to support GMP audits.

Beyond the product itself, VCR delivers comprehensive value through end-to-end services including consulting, design, and installation. VCR’s experienced engineering team accompanies clients from the initial site survey and solution design to final project handover. Any operational issues are resolved promptly thanks to a dedicated maintenance team available in both Hanoi and Ho Chi Minh City.

What sets VCR apart from many other providers in the market is its ability to customize Clean Booths according to actual needs. From small-scale projects in the cosmetics industry to large-scale pharmaceutical lines requiring ISO 5 clean level, VCR can always design optimized solutions that not only comply with international standards but are also adapted to Vietnam’s operating conditions. This advantage makes VCR the top choice for businesses seeking a reliable and long-term partner.

With the vision “Cleanroom for Better Life,” VCR not only supplies GMP-compliant equipment but also acts as a strategic partner, helping enterprises enhance production capacity and reinforce their reputation in both domestic and international markets. The combination of high-quality products, project expertise, and professional after-sales service has enabled VCR to earn strong trust within Vietnam’s business community.

5. GMP-Compliant Clean Booth Implementation Process

A GMP-compliant Clean Booth is evaluated not only by its technical quality but also by the entire implementation process, from design and manufacturing to installation and handover. In Vietnam, VCR has established a standardized process that ensures each Clean Booth project fully meets GMP requirements and aligns with the practical needs of enterprises.

The first step is site survey and requirement assessment. VCR’s engineers visit the factory to assess installation space, production scale, required clean class, and specific conditions such as temperature, humidity, or cross-contamination risks. This stage is crucial to determine where the Clean Booth should be installed, which production step it will serve, and what configuration is needed for optimal performance.

Next is the preliminary design. A 3D simulation drawing is created based on survey data, helping enterprises visualize the Clean Booth layout, airflow direction, HEPA filter position, lighting, fan placement, and other technical details. The design not only complies with GMP and ISO 14644 but is also optimized for easy maintenance, scalability, and potential relocation in the future.

Once the design is approved, the process moves to manufacturing and filter integration. VCR uses certified materials such as SUS304 stainless steel for the frame and panels, combined with imported HEPA or ULPA filters that are batch-tested for quality. Manufacturing takes place in VCR’s workshops with modern technologies like CNC cutting, laser welding, and surface treatment, ensuring durability and precision in every detail. All components undergo rigorous quality checks before being shipped.

The next step is on-site installation and calibration. Clean Booth modules are delivered and assembled directly at the factory. VCR’s engineering team performs pressure testing, airflow velocity measurement, filtration efficiency checks, and full system calibration to guarantee the clean zone meets the required class. All measurement data is documented in technical records to support GMP audits.

Finally, the project is handed over and commissioned, along with complete documentation including material certificates, testing results, and detailed user guides. VCR also provides after-sales and periodic maintenance services, including HEPA filter replacement, airflow verification, and system cleaning. This ensures the Clean Booth maintains stable performance for years, minimizing the risk of production disruptions.

Thanks to its standardized, transparent, and internationally compliant process, VCR has become a trusted partner for many pharmaceutical, food, cosmetics, and electronics enterprises in Vietnam. This serves as clear proof of VCR’s professional capacity and long-term commitment to clients.

6. Practical Applications of Clean Booths in Vietnam

Clean Booths are no longer just a technical concept but have become an essential solution across multiple industries in Vietnam. Each industry has its own specific requirements, and Clean Booths have consistently proven their value by ensuring GMP compliance while helping enterprises maintain stable product quality and strengthen brand reputation.

In the pharmaceutical industry, Clean Booths are commonly used in weighing areas, where the risk of pharmaceutical dust dispersion and cross-contamination is very high. With laminar airflow and certified HEPA filters, Clean Booths create localized clean zones, preventing fine dust from spreading throughout the entire facility. This not only protects material quality but also safeguards operators. Many pharmaceutical factories in Vietnam have adopted Clean Booths at this stage as a mandatory measure for GMP-WHO certification.

In the food and beverage sector, Clean Booths are installed in final packaging lines. This is the most critical stage, as finished products are still vulnerable to cross-contamination before sealing. Clean Booths create sterile environments with positive pressure to prevent unfiltered air from entering, ensuring absolute protection for packaging and final products. As a result, businesses can confidently launch products to the market that meet strict food safety standards in both domestic and international markets.

In the cosmetics industry, Clean Booths play a vital role in filling, bottling, and tube-sealing processes. Since cosmetics come into direct contact with human skin, safety and cleanliness are non-negotiable. Clean Booths maintain sterile airflow at production points, eliminating contamination risks and ensuring products like creams, serums, and perfumes remain pure and high-quality. This is also a key requirement for Vietnamese cosmetics companies to achieve ISO 22716 certification and export successfully to demanding markets such as the EU and Japan.

In electronics and precision component manufacturing, Clean Booths are deployed in semiconductor, sensor, and module assembly areas. These products are extremely sensitive to microscopic particles—even a 0.5-micron dust particle can damage an entire circuit board. With efficient air filtration and laminar airflow control, Clean Booths are the optimal solution for protecting components during production. Electronics factories in Bac Ninh, Bac Giang, and Ho Chi Minh City have already integrated Clean Booths into their high-precision lines, significantly improving product yield and reducing technical errors.

Overall, Clean Booths not only meet GMP theoretical requirements but also demonstrate proven effectiveness in real-world applications across Vietnam’s industries. From pharmaceuticals and food to cosmetics and electronics, Clean Booths serve as an “invisible shield,” protecting products from contamination risks while empowering enterprises to strengthen their credibility and competitive edge in the market.

7. Frequently Asked Questions About GMP-Compliant Clean Booths

Can a Clean Booth achieve ISO 5 cleanliness level?

Yes. A Clean Booth can be designed to reach ISO 5 cleanliness level when equipped with ULPA H14 filters and a laminar airflow system. With the right configuration, a Clean Booth can eliminate up to 99.999% of particles as small as 0.12 microns, meeting the stringent requirements of sensitive industries such as sterile pharmaceutical manufacturing or semiconductor production.

Is a Clean Booth movable?

Yes. One of the key advantages of a Clean Booth is its mobility. With a modular design featuring stainless steel frames and detachable panels, enterprises can easily relocate the Clean Booth to another area or reassemble it to fit production expansion needs. This helps save investment costs compared to constructing a permanent cleanroom.

What is the lifespan of HEPA filters in a Clean Booth?

Typically, HEPA filters in a Clean Booth last between 1 to 2 years, depending on the production environment and daily operating hours. To maintain optimal performance, enterprises should regularly check airflow and pressure across the filters, and replace them as recommended by the manufacturer.

How much does it cost to install a GMP-compliant Clean Booth?

The investment cost of a GMP-compliant Clean Booth depends on its size, required clean class, material specifications, and filtration system configuration. In general, prices range from several hundred million to several billion VND. Enterprises are advised to consult directly with the supplier for a detailed quotation and a solution tailored to their budget and production requirements.

Does the supplier provide GMP validation documentation?

Yes. Reputable suppliers such as Vietnam Cleanroom (VCR) always provide complete technical documentation, including HEPA/ULPA filter certificates, SUS304 stainless steel material certificates, design drawings, and inspection results. These documents are essential for enterprises to successfully pass GMP audits by regulatory authorities.

8. Contact VCR to receive offers and support from experts

Are you looking for a GMP-compliant Clean Booth supplier in Vietnam to enhance your production quality and meet international standards? The best solution is to partner with Vietnam Cleanroom (VCR) - a pioneer brand in the cleanroom equipment industry. With over 10 years of experience, VCR has delivered hundreds of projects for pharmaceutical, food, cosmetics, and electronics enterprises, committed to providing GMP - ISO 14644 certified products, dedicated technical services, and optimized costs.

Contact us today to receive:

- Free consultation on Clean Booth solutions tailored to your production scale and needs.

- Detailed and transparent quotations, along with complete technical documentation for GMP validation.

Hotline: 090.123.9008

Email: [email protected]

Website: https://cleanbooth.vn/

Diep VCR