HACCP‑Standard Clean Booths Help Food Plants Control Cross‑Contamination and Maintain a Clean Production Environment in Packaging / Filling Zones with a modular design, HEPA filtration, FFU units, this equipment meets ISO 22000 and FDA requirements, suitable for companies aiming at high quality and export markets.

- 1. What Is an HACCP‑Compliant Clean Booth?

- 2. Criteria for Selecting a Provider of HACCP‑Standard Clean Booths

- 3. VCR — A Reputable Provider of HACCP‑Standard Clean Booths

- 4. Implementation Process of Clean Booths in Food Plants (VCR Methodology)

- 5. Benefits of Collaborating with VCR

- 6. FAQ – Frequently Asked Questions

1. What Is an HACCP‑Compliant Clean Booth?

Definition and role in the food industry

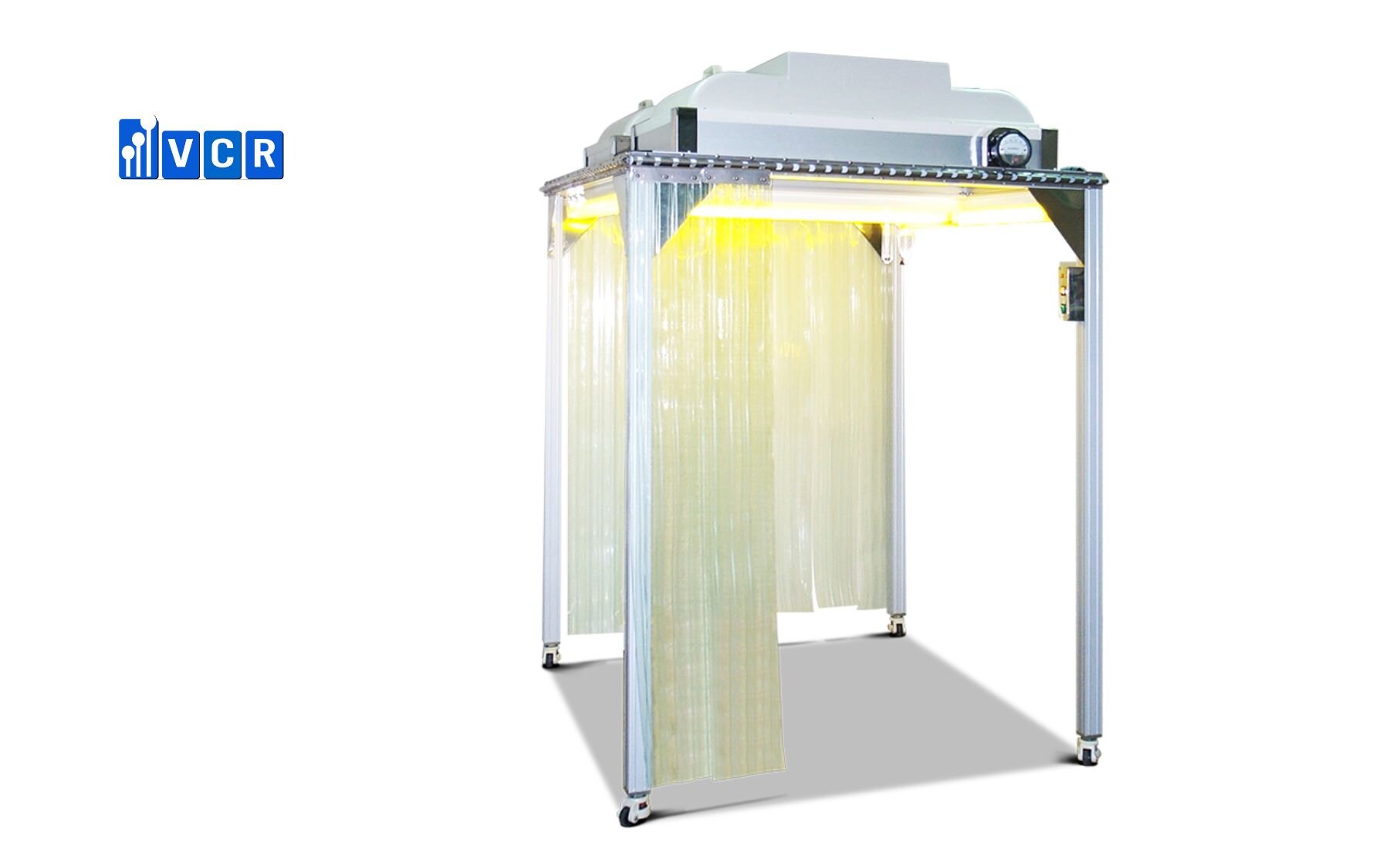

A Clean Booth is a sort of mobile clean room, modular in design, with frames of stainless steel or extruded aluminum, bounded by PVC curtain or panels. Inside it is equipped with air filtration systems like HEPA filters and FFU (Fan Filter Units) to create a clean environment at ISO Class 5 to 8 levels.

In the food industry, Clean Booths act as a “shield” to protect critical zones—such as raw material handling, packaging, or filling—from dust, microorganisms, and contaminants. It is a cost‑effective solution to maintain a clean environment while ensuring food safety.

What is HACCP? Why a Clean Booth must comply with HACCP

HACCP (Hazard Analysis and Critical Control Points) is a food safety management system based on hazard analysis and controlling critical points. Ensuring equipment—such as a Clean Booth—complies with HACCP is mandatory in modern food factories.

When a Clean Booth is designed on HACCP principles, it helps to:

-

Clearly segregate zones with high contamination risk

-

Minimize cross‑contamination between process stages

-

Support hazard control throughout the production chain

Benefits when a food plant uses an HACCP Clean Booth

-

Control cross‑contamination from microbes and dust: The Clean Booth acts as a positive‑pressure controlled zone, filtering air before it enters the production area, thereby reducing the risk of microbial or particulate contamination—one of the primary causes of food safety failures.

-

Simplify traceability and quality checks: Separating zones via Clean Booths makes it easier to monitor production steps and support traceability in internal audits or regulatory inspections.

-

Meet international certification standards (FDA, ISO 22000, etc.): HACCP‑compliant Clean Booths are often integrated with standards like:

-

FDA (U.S.): high requirements on hygiene in food production

-

ISO 22000: international food safety management system

-

ISO 14644‑1: classification of air cleanliness in clean rooms

-

Thus, factories not only ensure product quality but also elevate credibility when exporting to strict markets like the U.S., EU, or Japan.

Read more: Latest price list of Clean Booth used in electronics factory

2. Criteria for Selecting a Provider of HACCP‑Standard Clean Booths

Choosing a Clean Booth supplier should go beyond cost. More importantly, it should assess the provider’s ability to meet HACCP standards and their practical experience in the food sector. Here are key criteria to consider:

Experience in the food industry

A provider with actual implementations in food factories will understand specific requirements such as:

-

Production flows for different food categories (bakery, meat/fish, seasonings, beverages)

-

Proper placement in the facility’s zoning

-

Critical control points that need protection via clean zones

A provider with a transparent portfolio and proven clients gives greater confidence in expertise and quality assurance.

Flexible configuration adapted to processing space

Not all plants have ideal space for fixed clean rooms. Therefore, a Clean Booth should be modular and flexible, allowing adjustments in size, height, and filter placements.

Important attributes:

- Ease of relocation when layout changes

- Easy dismantling for cleaning and maintenance

- Good integration with worktables, packaging machines, conveyors

Food‑safe materials and certified components

A central factor for Clean Booths in food settings is cleanliness and safety of materials and equipment. Key requirements include:

-

Frame made of aluminum or stainless steel (304) — corrosion resistant

-

PVC/PU curtains not containing toxins, compliant with food contact standards

-

FFU fans, lighting, and electrical components meeting CE or RoHS standards

The provider should also be able to present product certifications and clear technical documentation.

Turnkey design — installation — maintenance service

In the food sector, timing is critical. A reliable provider offers a one‑stop service including:

-

Consulting on HACCP‑compliant solutions

-

Layout and technical drawings

-

Manufacturing, transportation, and installation

-

Regular maintenance and spare parts supply

Having a closed workflow helps ensure schedule control and reduce operational risk.

Technicians with HACCP & GMP understanding

Beyond installation skills, the provider’s technical team should be knowledgeable about food safety standards:

-

HACCP: hazard analysis and critical control

-

GMP: good manufacturing practices, control of facility environment

Such knowledge enables the provider to advise optimal solutions and avoid design mistakes that compromise hygiene.

Read more: Clean Booth or Fixed Clean Room: Which Solution is More Flexible?

3. VCR — A Reputable Provider of HACCP‑Standard Clean Booths

About VCR

VCR Cleanroom Equipment Co., Ltd is a pioneer in delivering clean room solutions, especially HACCP‑compliant Clean Booths for the food processing industry. With years of experience and engineers well versed in HACCP, GMP, and ISO, VCR has partnered with hundreds of factories nationwide to build safe production environments, controlling microbial and cross‑contamination risks.

Notable projects in food sector

-

A meat processing and packaging plant in Bac Giang — Clean Booths integrated with FFU units to control cutting and tray packing zones

-

Confectionery factory in Long An — design for filling zones achieving ISO Class 7

-

Seafood export processing facility in Can Tho — segregated zones for raw handling and packaging to prevent salinity / microbial interference

All projects are custom designed per plant layout and meet food safety and traceability standards.

Advantages of VCR‑supplied Clean Booths

-

Modular, easy‑to-maintain structure: VCR’s Clean Booths use 304 stainless or aluminum frames; modular design allows quick assembly, relocation, and ease of cleaning.

-

HEPA/ULPA and FFU filtration integration: VCR equips Clean Booths with FFU units coupled with HEPA or ULPA filters that can filter particles down to 0.3 microns with up to 99.999 % efficiency. This ensures:

-

Control of fine dust and microbes

-

Clean zones meeting ISO Class 5–8

-

Positive pressure to block ingress of contaminated air

-

-

Customized to plant layout

Instead of fixed templates, VCR conducts site surveys and delivers:-

Custom 2D/3D drawings based on floor plan and production flow

-

Analysis of personnel and material flow to optimize layout

-

HACCP‑based clean zoning to avoid overlaps

-

-

Standards compliance: HACCP, ISO 14644‑1 Class 5–8

VCR’s Clean Booths are manufactured, inspected, and accepted in compliance with:-

HACCP principles of hazard control

-

ISO 14644‑1 (air cleanliness classification)

-

Alignment with ISO 22000, GMP, FDA

Thus, products suit both domestic plants and exporters, helping enterprises more readily achieve international certification.

-

Read more: Latest price list of Clean booth used in food factory

4. Implementation Process of Clean Booths in Food Plants (VCR Methodology)

VCR applies a strict 5‑step process for each Clean Booth project, ensuring HACCP compliance while adapting to each plant’s reality. This ensures clients can control schedule, optimize cost, and guarantee reliable operation.

| Step | Task | Objective |

|---|---|---|

| 1 | Survey & requirement analysis | Inspect current plant, record production needs and zones requiring control |

| 2 | Layout & technical consultation | Propose Clean Booth layout, determine cleanliness class and movement flow |

| 3 | Design – Estimation – Approval | Produce 2D/3D drawings and detailed quotation approved by client |

| 4 | Fabrication – On‑site installation | Manufacture modules, FFU, PVC curtains; transport, install, connect power |

| 5 | Testing & handover | Test cleanliness, pressure, lighting; deliver, instruct in operation & maintenance |

Key highlights in their process:

-

Flexibility: adjust design quickly as layout changes

-

Cost optimization: use in‑stock materials, short installation time

-

After‑sales support: HACCP operation guidance, supply of genuine spare parts

5. Benefits of Collaborating with VCR

In the food industry – where safety and sanitation are top priorities – selecting the right Clean Booth provider makes a substantial difference in production efficiency and certification success. Below are concrete benefits when partnering with VCR:

Tailored solutions for each production line

VCR analyzes each customer’s specific processes (raw handling, packaging, filling) and configures Clean Booths to control cross‑contamination at critical points.

This ensures not only cleanliness, but also efficient, sustainable operation in compliance with audits and HACCP requirements.

Guaranteed timeline and quality

VCR builds a clear production and installation schedule with controlled checkpoints. Commitments include:

-

On‑time installation even during peak seasons

-

Testing of pressure, cleanliness, noise before handover

-

Complete technical and inspection documentation

These are essential for many factories to meet ISO 22000 and export certification.

Free consulting on HACCP & ISO standards

VCR is not just a vendor but a technical partner:

-

Advises on clean layout per GMP & HACCP

-

Guides sanitation procedures and periodic audits

-

Recommends suitable materials to satisfy ISO, FDA inspections

Consulting is offered free of charge, helping customers save consulting costs while meeting high standards.

Long‑term warranty & 24/7 technical support

VCR provides explicit long warranties:

-

Structural warranty of Clean Booth: 12 to 24 months

-

Replacement parts (FFU, curtains, lighting) during the life cycle

-

Technical support (remote or onsite) within 24 hours of request

This ensures stable operations with minimal downtime, even during peak production periods.

Read more: GMP Standard Clean Booth Supplier in Vietnam

6. FAQ – Frequently Asked Questions

Do food factories need Clean Booths?

Yes. Clean Booths play a critical role isolating high‑hygiene zones like raw handling, packaging, or filling. A controlled clean environment helps prevent cross‑contamination from microbes, fine dust, and pollutants, thereby maintaining product quality and ensuring compliance with HACCP and ISO 22000.

Does VCR support nationwide installation?

Yes. VCR has engineers and technical staff in all provinces. They are ready to survey, consult, and install anywhere in the country. VCR commits to accompany clients from consulting – design – installation – maintenance across North, Central, and South Vietnam.

Can a Clean Booth be used in preprocessing areas?

Absolutely. Clean Booths are ideal for raw material handling, sorting, filling, or packaging zones—which are high risk for contamination. Their flexible design and ease of installation make them suitable for new plants or retrofit projects.

How long does it typically take to install a Clean Booth?

Usually 3–10 working days, depending on the area, technical configuration, and customizations according to plant layout. VCR commits to swift, safe implementation without disrupting existing production.

Looking for a HACCP‑certified Clean Booth for your food factory?

Need a clean zone design to manage cross‑contamination, or pass ISO / FDA audits?

Partner with VCR — specialist in Clean Booth design & installation for the food industry

- Free consultation based on real layout

- Nationwide installation, long warranty

- Compliance with HACCP, ISO 14644‑1, ISO 22000 standards

Contact

Hotline: 090.123.9008

Email: [email protected]

Website: https://cleanbooth.vn/

Dat VCR