Clean Booth mini is a “miniature clean room” solution that helps laboratories create clean working areas without the need for permanent construction. With a compact, flexible design and integrated HEPA filtration system, Clean Booth mini provides a clean environment that meets standards, saving investment and operating costs.

- 1. What is a Clean Booth Mini? What is it used for in laboratories?

- 2. Why is the Clean Booth Mini a cost-effective solution for laboratories?

- 3. Structure & Operation Principle of the Clean Booth Mini

- 4. When should you choose a Clean Booth Mini instead of a traditional cleanroom?

- 5. Industries That Commonly Use Clean Booth Minis

- 6. Selection Guide & Add-On Options for Clean Booth Minis

- 7. Quick Answers About Clean Booth Minis

- 8. Need Consultation or Want to Order a Clean Booth Mini?

In the context of modern laboratories increasingly requiring clean and flexible operating environments, the mini Clean Booth solution is emerging as the optimal choice. Helping to quickly create local clean zones without having to build a fixed clean room, the mini Clean Booth is not only cost-effective but also flexible in application - ideal for R&D projects, microbiological testing or sample production. Let VCR learn more about how the mini Clean Booth works, why it is suitable for small laboratories and what to know when choosing this device.

1. What is a Clean Booth Mini? What is it used for in laboratories?

A Clean Booth Mini is a compact, mobile cleanroom enclosure designed to create a localized clean zone without requiring permanent construction. Unlike traditional cleanrooms, this type of booth operates as a “portable clean environment” that can be installed directly within an existing laboratory space.

Basic components of a Clean Booth Mini:

- Lightweight aluminum or stainless-steel frame, easy to assemble

- Transparent PVC curtains or acrylic panels to block external contamination

- HEPA/ULPA filtration system integrated into FFU (Fan Filter Unit), creating a laminar flow clean air stream

- LED lighting, power outlets, and optional modules

Common applications in laboratories:

Clean Booth Minis are typically used to establish a controlled environment for specific tasks requiring particle or microbial contamination control:

- Sample preparation: Protecting samples from cross-contamination during handling

- Chemical weighing: Preventing air turbulence from affecting precision balances

- Rapid testing: Providing a clean zone for microbiological tests, material inspections, or equipment setup

Instead of investing in a full-scale cleanroom system, a Clean Booth Mini helps laboratories reduce costs while still meeting cleanliness requirements for critical operations.

See more: Latest price list of Clean booth used in food factory

2. Why is the Clean Booth Mini a cost-effective solution for laboratories?

In today’s research and testing environments, minimizing cost while maintaining contamination control is crucial. The Clean Booth Mini has emerged as an ideal solution—cost-effective, efficient, and flexible.

Detailed comparison: Clean Booth Mini vs. Traditional Cleanroom

|

Criteria |

Clean Booth Mini |

Traditional Cleanroom |

|

Investment cost |

3-5 times lower |

High, requires permanent infrastructure |

|

Mobility |

Easy to assemble/disassemble, on wheels |

Fixed after construction |

|

Installation time |

Ready to use in 1-2 days |

Weeks to months |

|

Maintenance |

Simple, regular filter replacement |

Complex, requires technical expertise |

Key advantages of choosing a Clean Booth Mini:

- No structural renovation required: Can be deployed in existing lab rooms

- Customizable configuration: Size, cleanliness level, and FFU quantity can be adjusted

- Low cost - fast results: Ideal for small labs, short-term R&D projects, or time-limited clean operations

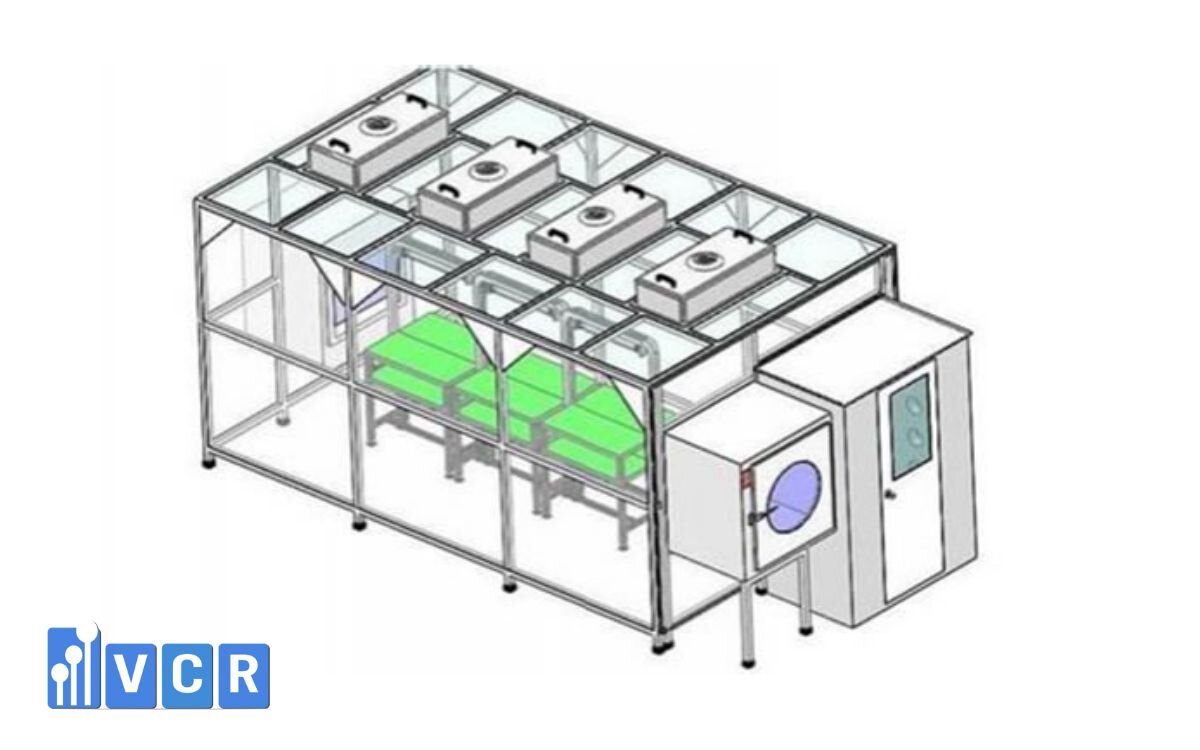

3. Structure & Operation Principle of the Clean Booth Mini

The Clean Booth Mini functions as a compact mobile cleanroom with a simple yet effective structure designed to control air cleanliness.

Standard components include:

- Aluminum or stainless-steel frame → Durable, corrosion-resistant, and easy to assemble, suitable for lab environments

- PVC curtains or acrylic panels → Blocks outside contamination and allows clear visibility inside

- FFU (Fan Filter Unit) system → Equipped with HEPA or ULPA filters that eliminate up to 99.99% of ≥0.3 micron particles, maintaining ISO 5 to ISO 8 cleanliness levels

- LED lighting and optional power outlets → Enhances convenience for technical tasks, optional UV lights and fan speed controllers

Operation principle: Laminar airflow for clean environment

The Clean Booth Mini uses a laminar flow system—clean air is directed in a unidirectional stream (vertical or horizontal) to:

- Prevent contaminated air from entering the working zone

- Push out particles and maintain clean working conditions

Ambient air is pulled into the FFU → filtered through HEPA → pushed into the clean area → maintaining a stable clean zone inside the booth.

See more: Clean Booth or Fixed Clean Room: Which Solution is More Flexible?

4. When should you choose a Clean Booth Mini instead of a traditional cleanroom?

You don’t always need a full cleanroom with high setup costs and long build times. A Clean Booth Mini is a practical alternative in the following scenarios:

- R&D projects or small-scale laboratories

Research and development often involves temporary setups and rapid testing cycles. A Clean Booth Mini enables:

- Quick deployment of a clean working area

- Easy relocation between rooms or projects

- No need for renovation permits or facility upgrades

- Limited workspace

Its compact size allows it to fit into tight spaces like shared labs or technical corridors. Ideal when:

- Building a dedicated cleanroom is not feasible

- You need to control contamination at a specific workstation (e.g., weighing bench)

- Flexible usage needs - by shift or by task

Some labs only require cleanliness during specific procedures (e.g., sampling, packaging). Clean Booth Minis:

- Can be turned on/off when needed → saving energy

- Easily relocated to different areas depending on task flow

- Budget constraints but cleanliness still required

With investment costs at only 1/3 to 1/5 of a traditional cleanroom, Clean Booth Minis help maintain cleanliness standards without financial strain, suitable for:

- Biotech startups

- University or institutional research labs

- SMEs needing to meet audit or compliance requirements

See more: Provider of HACCP‑Compliant Clean Booths for Food Processing Plants

5. Industries That Commonly Use Clean Booth Minis

Clean Booth Minis are not only popular due to their affordable price, but also because of their wide range of applications across multiple industries. Below are some of the key sectors where this type of clean enclosure is frequently used for testing, production, or research.

Pharmaceutical Industry

- Application: Solvent preparation, weighing active ingredients, preparing samples before analysis

- Why it's used: Particle, microbial, and cross-contamination control are mandatory under GMP standards. The Clean Booth Mini creates a localized clean zone with ISO 5-7 cleanliness in weighing rooms or intermediate labs.

Food Industry

- Application: Microbiological testing, analysis of raw materials and finished products

- Why it's used: Protects samples from environmental contamination—especially important for detecting microorganisms such as E. coli, Salmonella, or mold spores.

Electronics & Semiconductor Industry

- Application: Small-scale assembly, PCB testing, SMD soldering

- Why it's used: Maintains a clean workspace to reduce dust, which can cause circuit defects, short circuits, or decrease component lifespan.

Cosmetic Industry

- Application: Ingredient verification, sample testing, pilot-scale packaging

- Why it's used: Many handmade cosmetic producers require clean zones that meet ISO 8 or GMP-equivalent standards. Clean Booth Minis fulfill these needs without building a full cleanroom.

6. Selection Guide & Add-On Options for Clean Booth Minis

To choose the right Clean Booth Mini, consider your available workspace, required cleanliness level, and any additional features needed for your workflow. Below are common configurations and recommended expansion options:

Standard Sizes (Reference)

|

Model Code |

Dimensions (L×W×H) |

Number of FFUs |

Recommended Use Cases |

|

CBM-10 |

1000 x 1000 x 2000 mm |

1 |

Chemical weighing, sample preparation |

|

CBM-12 |

1200 x 1500 x 2000 mm |

1-2 |

Solvent mixing, group operations |

|

CBM-Custom |

As specified by customer |

Flexible |

Electronics assembly, handmade cosmetics |

Cleanliness Levels Based on FFU Configuration

|

Filter Type |

Filtration Efficiency |

Achievable Cleanliness Level* |

|

HEPA H14 |

≥99.995% @ 0.3μm |

ISO 7 - ISO 8 |

|

ULPA U15 |

≥99.9995% @ 0.12μm |

ISO 5 - ISO 6 |

* Based on ISO 14644-1. Final cleanliness also depends on airflow rate and room sealing.

Common Optional Features

- Differential pressure gauge → Monitors filter performance and alerts when replacement is needed

- UV disinfection lamp → Enhances microbial control before or after work shifts

- Lockable caster wheels → Allows mobility while maintaining stability during operation

See more: Clean Booth inspection checklist before putting into production

7. Quick Answers About Clean Booth Minis

1. Does a Clean Booth Mini meet ISO standards?

→ Yes. Depending on FFU configuration and room conditions, Clean Booth Minis can meet ISO 5 to ISO 8 standards, suitable for most lab and production needs.

2. Can it be used in a non-cleanroom environment?

→ Absolutely. The Clean Booth Mini creates a localized clean zone using a laminar airflow system (draw-filter-blow), ensuring contamination control even in standard environments.

3. Is maintenance complicated?

→ No. The system is simple to maintain:

- Replace HEPA/ULPA filters periodically (every 6-12 months, depending on usage)

- Clean the frame, curtains, and lighting with alcohol or dry cloths

4. Can additional equipment be installed inside the booth?

→ Yes. The Clean Booth Mini supports optional equipment such as:

- UV sterilization lamps

- Electronic balances, measuring devices

- Power outlets, work trays, tool racks

Tip: When ordering a Clean Booth, specify the devices to be used inside so the layout can be optimized to avoid airflow disruption.

8. Need Consultation or Want to Order a Clean Booth Mini?

Whether you're operating a pharmaceutical lab, food testing facility, or handmade cosmetics workshop, the Clean Booth Mini is a cost-effective, flexible, and easy-to-deploy solution.

Why choose a Clean Booth from VCR?

- Industry-specific consultation (pharma - food - electronics - cosmetics, etc.)

- Quick installation within 1-2 days

- Various configurations - custom designs available

- On-site maintenance, filter replacement, and warranty service

Contactus now for technical consultation and a detailed quote:

Let me know if you want this formatted into a full blog layout or exported to a specific format.

Hotline: 090.123.9008

Email: [email protected]

Website: https://cleanbooth.vn/

Diep VCR