Clean Booth for cosmetic R&D is becoming a prominent trend in 2026 thanks to its ability to control cleanliness, prevent contamination and protect operators during formula testing. With a flexible design, easy to install and ISO 22716 standard, Clean Booth helps optimize the modern cosmetic research process.

- 1. The Increasing Importance of Clean Booths in Cosmetic R&D

- 2. Automation and IoT Integration: A Key Trend for 2026

- 3. Modular Design: Optimizing R&D Space and Budget

- 4. Antibacterial and Easy-to-Clean Materials on the Rise

- 5. Compliant with ISO 22716 & ESG Standards

- 6. Comparison: Traditional Clean Booth vs. 2026 Clean Booth

- 7. Recommended Clean Booth Configuration for Cosmetic R&D

- 8. Frequently Asked Questions

- 9. Need a Clean Booth for Your Cosmetic R&D Lab?

1. The Increasing Importance of Clean Booths in Cosmetic R&D

In the cosmetics industry, the research and development (R&D) stage is not just about testing formulas - it is where new products are born. It’s also the most sensitive phase in terms of contamination risks, formulation instability, and regulatory non-compliance. Clean Booths - also known as mobile cleanrooms - are becoming an increasingly preferred solution in laboratories due to three key advantages:

Optimizing the Formula Testing Process

When testing multiple formulations in an open lab environment, the risk of component changes due to dust and microorganisms is high. Clean Booths offer a strictly controlled environment (typically ISO Class 6-8), helping to:

- Ensure accuracy of ingredients in each formulation test

- Minimize contamination that could affect product performance and stability

- Reduce trial-and-error time and accelerate product development

Protecting Products and Operators

Cosmetic ingredients - especially preservatives and fragrances - can cause irritation with prolonged exposure. Meanwhile, serum, gel, or emulsion products are highly prone to contamination. Clean Booths help:

- Create a clean air barrier around the working zone

- Prevent cross-contamination between samples

- Protect operators from inhaling fine particles or volatile chemicals

Complying with ISO 22716 & GMP Standards

ISO 22716 (Good Manufacturing Practices for cosmetics) and GMP guidelines require controlled environments for experimental production. Clean Booths help R&D labs:

- Establish a compliant working zone without needing a full-scale cleanroom

- Easily separate zones for filling, weighing, and sample storage

- Increase approval rates during GMP audits or facility assessments

2. Automation and IoT Integration: A Key Trend for 2026

By 2026, Clean Booths will no longer be just physical clean spaces - they are transforming into smart, mini laboratories integrated with digital technology. Thanks to IoT and smart sensors, next-gen Clean Booths support cosmetic R&D with greater efficiency and traceability.

Integrated Particle and Microbial Sensors

Cosmetic samples - especially serums or creams - are highly sensitive to microbial and particulate contamination. Modern Clean Booths feature PM2.5/PM10 sensors or ISO 14644-compliant particle counters to:

- Continuously monitor airborne particle levels

- Alert when thresholds are exceeded (e.g., ISO 7: 352,000 particles/m³)

- Minimize formulation errors caused by environmental variation

Automatic Pressure Control and Alarms

To block contaminated air inflow, modern Clean Booths are pre-programmed for positive pressure control. These systems:

- Automatically adjust FFU fan speeds based on preset pressure differentials

- Trigger alerts for pressure fluctuations, clogged HEPA filters, or open doors

- Log environmental data for quality inspections and internal audits

Real-time Dashboard Integration

Sensor data is fed into a cloud-connected dashboard, viewable on computers or smartphones - enabling cosmetic R&D teams to:

- Monitor environmental conditions during formulation trials

- Retrieve historical test environment data

- Include reliable metrics in audit reports or standard registrations

See more: Clean Booth for the Pharmaceutical Sector: GMP Installation Checklist

3. Modular Design: Optimizing R&D Space and Budget

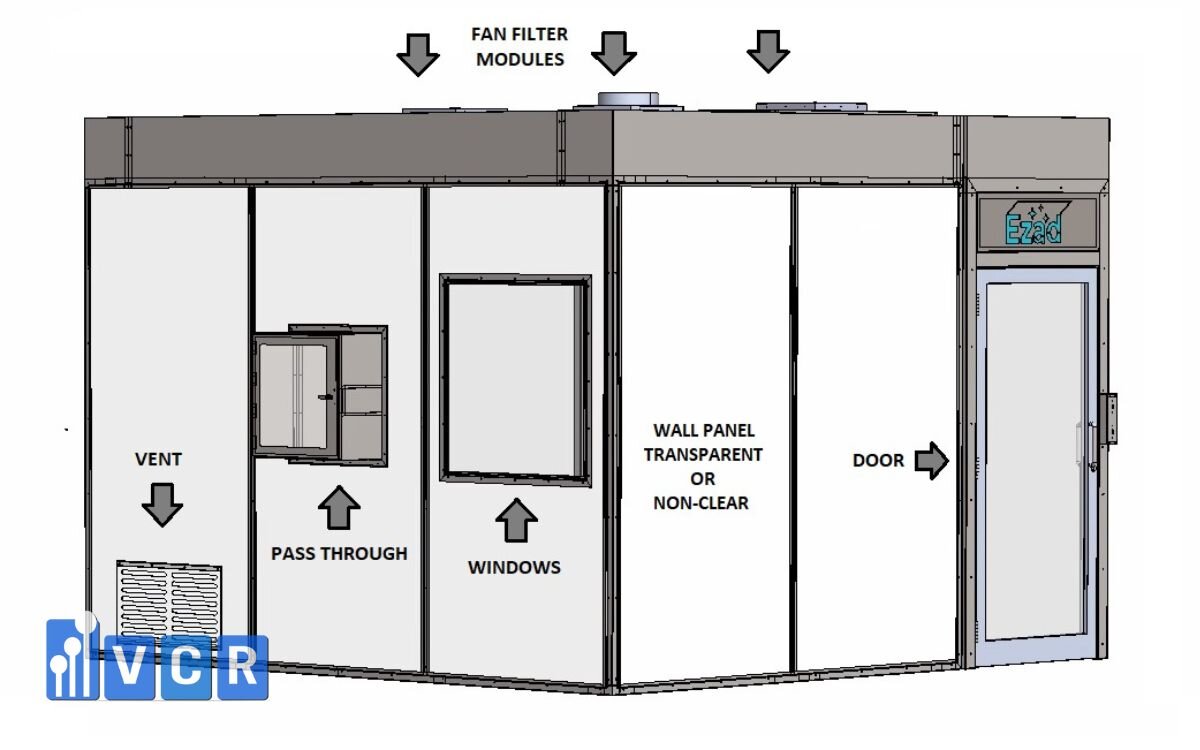

Unlike mass production facilities, cosmetic R&D spaces are often compact and frequently reconfigured depending on project needs. This is why modular Clean Booths are gaining popularity - offering flexible installation and cost-efficiency.

Suitable for Labs of All Sizes

Modern Clean Booths use aluminum profiles or stainless steel frames and can be:

- Installed in 1-2 days without modifying existing infrastructure

- Custom-sized to fit available space (e.g., 2×2m, 3×4m, etc.)

- Relocated or reassembled easily as lab layouts evolve

Scalable for R&D Growth

Each cosmetic development project follows a unique cycle - from ideation → formulation → sample testing → pilot production. Modular Clean Booths allow:

- Starting with basic setups (FFU + PVC curtain)

- Gradual upgrades: solid panels, touchscreens, interlocks, UV lighting

- Seamless scaling when expanding formulation capacity

Cost-efficient Entry Point

Rather than investing in permanent cleanrooms, cosmetic startups or mid-sized labs can:

- Use Clean Booths to create dedicated clean zones for key tasks (e.g., weighing, filling)

- Eliminate the need for a separate HVAC system

- Optimize limited budgets while still meeting ISO 7-8 clean conditions

4. Antibacterial and Easy-to-Clean Materials on the Rise

In cosmetic R&D labs, where sensitive tasks such as weighing ingredients, emulsifying, and trial filling take place, fast cleaning and contamination control are critical. The 2026 trend highlights a clear shift from conventional materials to advanced antibacterial and easy-to-clean surfaces in Clean Booth construction.

Prioritizing Stainless Steel 304/316L for Frame and Surfaces

- Stainless Steel 304 is widely used due to its durability, corrosion resistance, and cost-effectiveness

- Stainless Steel 316L, a premium option, is ideal for areas requiring high cleanliness (low pH, exposure to solvents)

- Smooth, non-porous surface: prevents dust accumulation and is easy to disinfect with alcohol or cleaning agents

Nano Silver-Coated Panels for Active Antibacterial Protection

- Composite panels can be coated with nano silver (Ag⁺) to:

- Inhibit bacterial growth on surfaces for 24-48 hours

- Reduce the need for constant disinfection with strong chemicals

- Ideal for shared spaces where cross-contamination risks are high

Tempered Glass - Clear Visibility and Easy Cleaning

- Instead of frosted plastic curtains or acrylic sheets, 2026 Clean Booths prioritize tempered glass panels, offering:

- Clear visibility for internal operations (suitable for product demo or training)

- No static attraction like acrylic, easily cleaned with a dry cloth or RO water

5. Compliant with ISO 22716 & ESG Standards

By 2026, Clean Booths serve more than just clean zones - they help cosmetic manufacturers meet both international quality standards and sustainability commitments (ESG). These dual advantages make Clean Booths a strategic investment for growth.

Meeting ISO 22716 - GMP Requirements for Cosmetics

ISO 22716, the global standard for Good Manufacturing Practices in cosmetics, demands strict environmental control during product trials. Clean Booths allow R&D labs to:

- Create controlled work zones without building full-scale cleanrooms

- Easily divide areas for weighing, blending, filling, and testing

- Prevent cross-contamination between test formulas

- Increase chances of passing GMP inspections at the R&D stage

Supporting ESG: Energy Efficiency & Eco-Friendly Materials

ESG (Environmental - Social - Governance) has become a mandatory standard across FMCG and cosmetic sectors. Next-gen Clean Booths integrate ESG elements such as:

- Energy-saving FFUs operating efficiently in ECO mode

- Reusable frame systems, generating less construction waste than fixed cleanrooms

- Recyclable composite panels that reduce environmental impact

- Low-consumption LED lighting that still meets ≥500 lux requirements

Summary: ISO 22716 is the "gateway" for product approval, while ESG is the "door opener" for long-term brand credibility. A modern Clean Booth empowers cosmetic R&D teams to achieve both - smartly and affordably.

See more: Latest price list of Clean Booth used in electronics factory

6. Comparison: Traditional Clean Booth vs. 2026 Clean Booth

With increasing R&D demands and the rise of sustainable manufacturing, Clean Booths are no longer just technical tools - they represent a lab’s quality and ESG capability. Here's a quick comparison:

|

Criteria |

Traditional Clean Booth |

2026 Clean Booth |

|

Filtration Level |

ISO Class 8 |

ISO Class 6 or better (depending on FFU + HEPA H14 setup) |

|

Smart Control |

Not available |

Equipped with particle sensors, pressure control, alerts |

|

Design |

Fixed, time-consuming to install, non-portable |

Modular, upgradable, and relocatable |

|

Materials |

Basic panels, hard to clean |

Stainless steel 316L, tempered glass, nano silver panels |

|

ESG Compliance |

Not addressed |

Yes: energy-efficient, recyclable materials, low emissions |

7. Recommended Clean Booth Configuration for Cosmetic R&D

To ensure operational efficiency, space optimization, and ISO 22716 compliance, here’s the ideal Clean Booth setup for modern cosmetic R&D labs:

Recommended Size: 6-12 m²

- Supports 1-3 staff working simultaneously

- Suitable zoning: weighing table - filling station - sample holding area

Filtration System:

- Ceiling-mounted FFUs with HEPA H14 filters

- Air velocity: 0.45 m/s ±20%

- Ensures ISO Class 7 or better

Lighting & Noise:

- Ceiling LED panels with ≥500 lux, neutral color temperature (4000-5000K)

- Operational noise: below 60 dB - suitable for focused work

Door System:

- Automatic sliding doors (single or double leaf)

- Integrated interlock system to prevent simultaneous access

- Optional features: safety sensors, observation glass, status indicator lights

8. Frequently Asked Questions

1. Should small-scale cosmetic R&D labs invest in a Clean Booth?

Yes. Even a compact Clean Booth (4-6 m²) can establish a controlled clean zone for sensitive procedures. It enables:

- Reduced risk of cross-contamination during formula trials

- Early compliance with ISO 22716 or GMP standards

- Easy expansion as R&D demands grow

2. What’s the difference between a Clean Booth and a fixed cleanroom?

|

Criteria |

Clean Booth |

Fixed Cleanroom |

|

Investment Cost |

Significantly lower |

High - requires structural renovation |

|

Setup Time |

1-3 days |

3-6 weeks or more |

|

Mobility |

Portable, easy to relocate |

Permanent, non-relocatable |

|

Best Use Case |

R&D, trials, localized clean areas |

Large-scale production |

Summary: Clean Booths are ideal for research environments with frequent process or layout changes.

3. How often should Clean Booths be maintained in cosmetic labs?

Recommended interval: Every 3-6 months, depending on:

- Usage frequency

- Type of product tested (liquid, emulsion, powder, etc.)

- Required cleanliness level of the area

Key maintenance checks include:

- HEPA H14 filter efficiency

- Pressure and particle sensor status (if applicable)

- Panel joints, air seals, and FFU vibration levels

9. Need a Clean Booth for Your Cosmetic R&D Lab?

Whether you're launching a small lab or preparing a certified R&D center, selecting the right Clean Booth configuration can save time, reduce costs, and prevent technical mistakes.

VCR’s engineering team has delivered hundreds of Clean Booth projects for the cosmetics sector - from local brands to international ODM manufacturers.

Free consultation available on:

- Custom configurations based on space, budget, and compliance level

- Required equipment for each stage of product development

- Modular upgrade paths and smart system integrations

Hotline: 090.123.9008

Email: [email protected]

Website: https://cleanbooth.vn/

Diep VCR